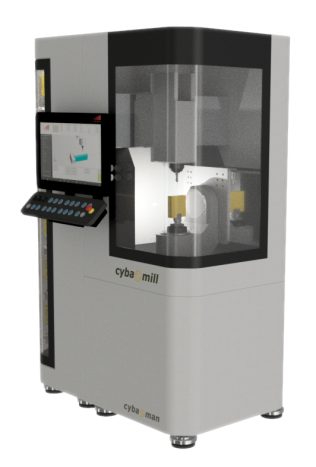

The new CybaMill

Cybaman Technolgies announces the new CybaMill product range

Cybaman Technologies have launched the new high-speed, high-accuracy milling machine on which the company will build the new product range.

After extensive consultation with existing customers significant improvements in machine specification, design and automation have been achieved to improve machine speed, accuracy and productivity.

cybaMill

The new cybaMill product line-up will be available in 4, 5 & 6 axes and include the following models:

- cybaMill 2020 : Standard

- cybaMill 2020 : Pro

- cybaMill 2020 : Ultra ( Linear and direct drive torque motors )

The cybaMill 2020 Ultra features high resolution linear sealed encoders and high torque direct drive linear/rotary servo motors.

Part Capture and Management

The machines pallet loader option has been updated and now features a new Part Capture and Management option, specifically for dental.

Parts can now be cut from the dental blanks and captured in individal trays reducing handwork, production times allowing parts to ship faster to the customers

The pallet loader and part management works independently from the machine allowing blanks and parts to be loaded and unloaded safely while the machine is running.

cybaCAST

The newly designed cybaMill series will also power the upcomming cybaCAST system for additive / hybrid manufacture including:

- cybaCAST : Additive

- cybaCAST : Hybrid : Combined Additive & Subtractive Milling

- cybaCAST : Subtractive : Milling & 3D Probing

The new cybaCAST Additive Additive machining system, now has the capability to operate as an additive manufacturing system using laser direct metal deposition or as a cybaCAST Hybrid , combined additive and subtractive machining system with the high speed milling spindle.

The cybaCAST additive technique, employing layer-by-layer laser fused metal deposition, enables the Cybaman system to produce components directly from a computer model with functional properties that have been shown to be largely equivalent to conventionally produced wrought and cast alloys.

Build materials currently include steels, steel alloys and titanium, and the concept has the capability to operate with a much larger range of materials, making the system ideally suited to a wide range of applications across multiple manufacturing sectors.

Unique features of the Cybaman design include the ability to achieve high volume deposition with multiple powders at the same type or mix different metals during the process to allow the deposition of alloys.

Precision control over the individual powder feed units guarantee repeatable results in terms of deposition rate, volume and material mix, in the case of alloys. Power for the deposition process comes in the form of a 400W SPI water cooled fibre laser, with options available for higher power lasers if required.